Factory

The location of the Plant was chosen after geological studies on quarries (limestone + clay + sand) which revealed that the raw materials is sufficient for 300 years

Medcom Aswan Cement plant is located at 110 km Aswan / Abu -Simbel Road – Aswan Governorate, the region established on area around one million m2 and designed to produce cement with capacity of 0.75 M tons per year.

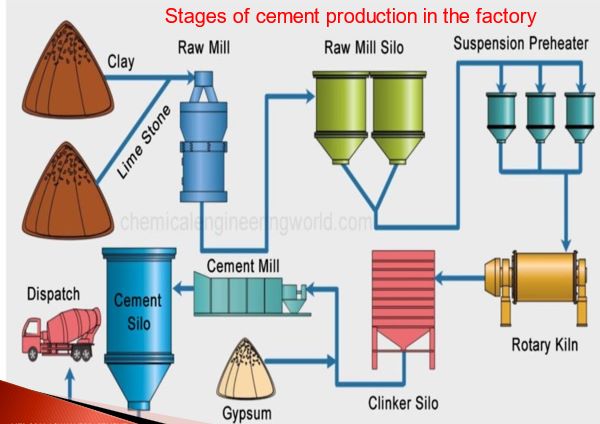

Cement Production process

(1) Mining the Raw Material

limestone and clay are extracted from the quarry and then transported by trucks to the crusher area.

(2) Crushing Process

The limestone is crushed with 80 mm max and the clay is crushed with 70 mm max

(3) Prehomogenization

The prehomogenization process for limestone and clay are carried out by using a Stacker, and the raw materials are swept on the belt by a Reclimer, which improves the homogenization process.

(4) Raw Material Mill

The raw materials are fed into the vertical raw mill by specified scales, The raw material is ground by vertical mill and stored in CF silo.

(5) Thermal Operations

Homogeneous raw materials are withdrawn with scales from the bottom of the raw silo to the multi-stage heating tower (5 stages),. then to the rotary kiln, allow slow material movement, and where high-temperature combustion gases is raised up to 1450 degrees where the raw material becomes clinker and goes out from the kiln into and cooler, where the clinker is cooled by air and stored

(6) Cement milling and packing

The clinker is ground by different-size steel balls, with calcium sulfate CaSO4.2H2O (gypsum) being added to extend cement setting times.

The cement is then housed in storage silos it will be packaged in 50 kg ± 2%, or supplied in bulk directly from the silos

All necessary Services and utilities wear made available to establish the plant. this includes construction of integrated transforms station which is fed directly with high voltage by the 220 k/volt from the High Dam. The station is equipped with two Czech-made transformers, each with a capacity of 25 MVA.

It is done using packing machines in the case of using sacks, where the weight of the sacks is 50 kg ± 2%, or bulk cement is packed directly from the silos in cars, according to the customer’s desire.